| 310S Stainless Steel Pipe & Tubes Specification | ASTM A269, ASTM A213, ASTM A312, ASME SA269, ASME SA213, ASME SA312 |

| 310S Stainless Steel Pipe & Tubes Grades | 202, 304, 304L, 304H, 304LN, 309S, 310S, 316, 316L, 316H, 316Ti,

316LN, 317L, 321, 321H, 347, 347H, 904L, SMO 254, ALLOY 254, 6MO,

6MOLY, UNS S31254 ETC. |

| 310S Stainless Steel Pipe & Tubes Type | Seamless / Welded / ERW / EFW / Cold Draw / Hot Finish / Cold

Finish |

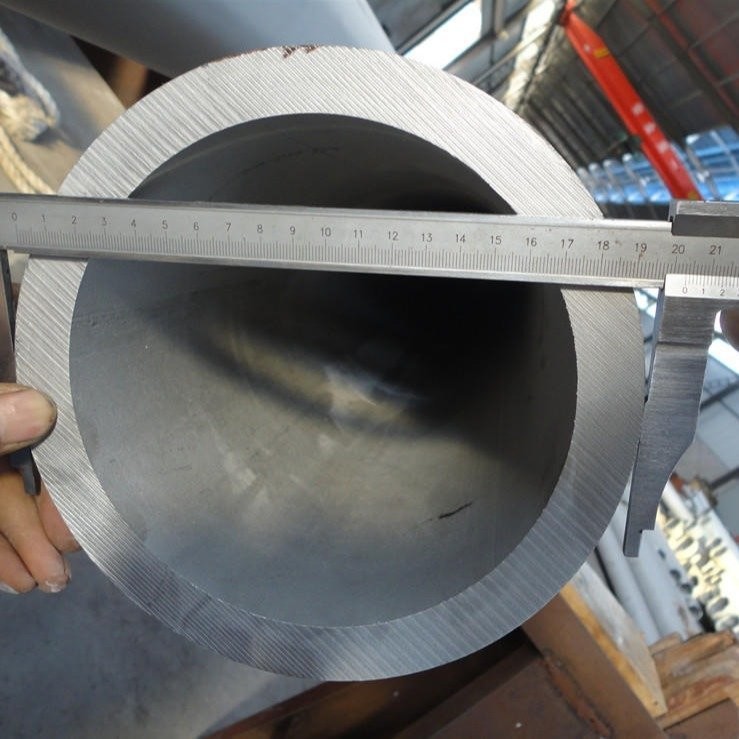

| 310S Stainless Steel Pipe & Tubes Outer Diameter Size | Seamless - 1/2" NB TO 18" NB

Welded / ERW- 1" NB TO 16" NB

EFW - 8" NB TO 110" NB |

| 310S Stainless Steel Pipe & Tubes Wall Thickness | Schedule 10 to Schedule 160 (3 mm to 100 mm Thickness) |

| 310S Stainless Steel Pipe & Tubes Length | 01 Meter to 12.5 Meters, Single Random Length, Double Random Length

And Customize Size. |

| 310S Stainless Steel Pipe & Tubes Ends | Plain Ends / Beveled Ends |

| 310S Stainless Steel Pipe & Tubes Delivery Conditions | As Rolled, Formed, Stress Relieved, Annealed, Hardened, Tempered,

Cold Draw |

| 310S Stainless Steel Pipe & Tubes Coating | Electropolish, Mechanical Polish, Satin Finish, Passivated |

| 310S Stainless Steel Pipe & Tubes Other Testing | Product Analysis, Transverse Tension Test, Flattening Test, Etching

Test, Radiograph HIC Examination, Stabilizing Heat Treatment,

Intergranular Corrosion Test, Weld Decay Test, Magnetic Particle

Detection, Grain Size Test, NACE 0175, Dual Grade, PWHT (POST WELD

HEAT TREATMENT), Flare Test, Bend Test, Hardness Test, Tensile Test

etc |

| 310S Stainless Steel Pipe & Tubes Dimension | All Pipes Is Manufactured and Inspected / Tested to the Relevant

standards includingASTM And ASME |

| 310S Stainless Steel Pipe & Tubes Value Added Services | Draw / Expansion / Machining / Sand Blasting / Shot Blasting / Heat

Treatment |

| 310S Stainless Steel Pipe & Tubes Packaging | Loose / Bundle / Wooden Pallet / Wooden box-a / Plastic Cloth Wraps

/ Plastic End Caps / Beveled Protector |

| 310S Stainless Steel Pipe & Tubes Shipment & Transportation | By Road - Truck / Train, By Sea - Break-bulk Conventional Vessel /

FCL (Full Container Load) / LCL (Less Container Load) / 20 Feet

Container / 40 Feet Container / 45 Feet Container / High Cube

Container / Open Top Container, By Air - Freighter Civil Passenger

and Cargo Planes |

| 310S Stainless Steel Pipe & Tubes Material Test Certificate | Manufacturer Test Certificate As Per EN10204 3.1, 3.2 / Laboratory

Test Certificate From NABL Approved Lab. / Under Third Party

Inspection Agency Like SGS, TUV, DNV, LLOYDS, ABS ETC |