Product Name: 2mm NM500 Wear Resistant Steel Plate

Product Introduction

Characteristics

WearTuf 500 is a fully martensitic Q&T abrasion resistant steel

having a hardness of average 450 Brinell. WearTuf 500 combines wear

resistant properties with excellent weldability and bending

performance. Due to the high impact toughness, WearTuf 500 offers

very good crack integrity.

Dimensions

WearTuf 500 is supplied in the thickness rage of 4.0 - 50.0 mm and

in the plate width of 900 – 3 100 mm. Supplied plate length from 4

000 to 18 000 mm.

Impact toughness

Typical 35J/-40°C (-40°F)

The impact toughness is given as absorbed energy at temperature,

being the average of three full size Charpy-V test samples in

longitudinal direction to rolling, according to EN ISO 148-1.

Hardness guarantee

Surface hardness: 470-530 Brinell

Guaranteed hardness range, measured on a milled surface at a depth

of 0.5 – 2.0 mm below the plate surface, according to ISO EN

6506-1.

Min center hardness:

Plate thickness ≤ 20mm: min 470 Brinell

Plate thickness > 20mm: 95% of min guaranteed surface hardness.

Applications

WearTuf 500 is mainly uesd within the mining and recycling

industry. Common applications are: heavy dumper and tipper bodies,

buckets, cutting edges, hammers, shredders, crushers, sieves and

various lining parts.

Ultrasonic testing

All plates delivered meets the Class E2, S2 requirement, according

to EN 10160.

Delivery condition

WearTuf 500 is delivered in the as quenched (Q) condition, and when

found necessary in the condition of quenched and tempered (QT).

The plates are delivered with sheared or thermally cut edges.

Tolerances

The thickness tolerances of WearTuf 500 meets and exceeds the

thickness tolerance of EN 10029 Class A . Tolerances on shape,

length, and width meets the requirements of EN 10029. Flatness

tolerances conforms to EN 10 029 Class S or closer.

Surface condition and properties

The delivered surface finish meets and exceeds that of EN 10163-2

Class A, Subclass 3.

The plates will be delivered as painted, using a low zinc silicate

corrosion protective shop primer. Plates can also be delivered as

unpainted.

Heat Treatment

Since the properties in the as delivery condition cannot be

retained after exposure at service temperatures above 250°C,

WearTuf 500 is not intended for further heat treatment.

Technical Data

Chemical CompositionLadle analysis: The steel is grain refined and fully killed, wt%

Thickness

(mm) | C

max | Si

max | Mn

max | P

max | S

max | Cr

max | Ni

max | Mo

max | B

max | CEV

Typical | CET

Typical |

|

|

| 4.0 – 12.0 | 0.27 | 0.60 | 1.20 | 0.02 | 0.01 | 1.00 | 0.50 | 0.30 | 0.004 | 0.48 | 0.34 |

| 12.1 – 25.0 | 0.29 | 0.60 | 1.50 | 0.02 | 0.01 | 1.30 | 0.70 | 0.50 | 0.004 | 0.61 | 0.41 |

| 25.1 – 50.0 | 0.29 | 0.60 | 1.60 | 0.02 | 0.01 | 1.30 | 0.90 | 0.60 | 0.004 | 0.66 | 0.44 |

CEV = C + Mn/6 + (Cr + Mo + V)/5 + (Ni + Cu)/15

CET = C + (Mn + Mo)/10 + (Cr + Cu)/20 + Ni/40

Mechanical PropertiesYield strength

Rp0.2 | Tensile strength

Rm | Elongation

A5 |

|

| 1250 MPa | 1600 MPa | 8% |

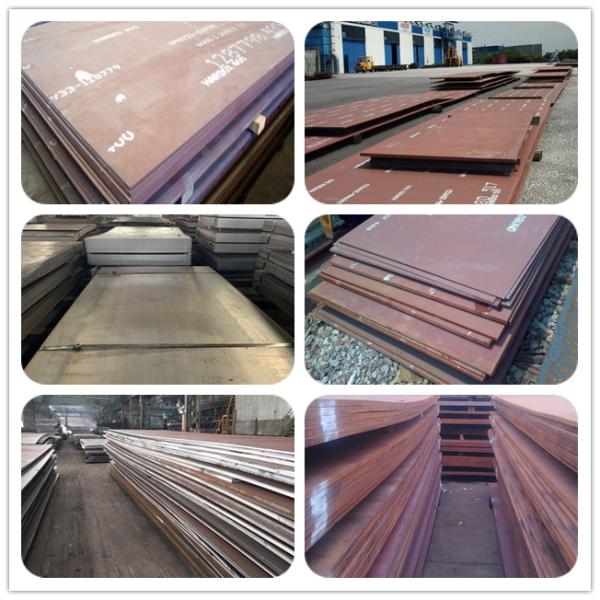

Pictures of 2mm NM500 Wear Resistant Steel Plate

Quality first

Our Certificates

About Us

FAQ

Q1. Where is your factory?

A1: Our company’s processing center is located in Zhengzhou, Henan,

China.

Which is well equipped with laser cutting machines, mirror

polishing machines, and related machines.

We can provide a wide range of personalized services according to

the customers’ needs.

Q2. What are your company's main products?

A2: Our main products are 1mm thick stainless steel shim

plate/sheet, coil, round/square pipe, bar, channel, etc.

Q3. How do you control quality?

A3: Mill Test Certification is supplied with shipment, Third Party

Inspection is available.

Q4. What are the advantages of your company?

A4: We have many professionals, technical personnel, more

competitive prices, and the best after-sales service than other

stainless steel companies.

Q5. How many countries have you already exported to?

A5: Exported to more than 50 countries mainly from America, Russia,

UK, Kuwait, Egypt, Turkey, Jordan, India, etc.

Q6. Can you provide a sample?

A6: Small samples in store and can provide the samples for free.

Customized samples will take about 5-7days.